This type of cable is specifically designed for internal wiring of distribution boards and distribution boxes, suitable for scenarios with AC rated voltage ≤ 1000V or DC rated voltage ≤ 750V.The installation method is typically laid through conduits or trunking, and it can also be used for internal wiring of electrical equipment, with a maximum operating temperature of up to 90°C.

Its core advantage lies in low smoke and non-corrosive — it does not release toxic gases or corrosive substances when burned, so it is particularly suitable for places sensitive to smoke and harmful gases (such as public buildings, government institutions, etc.), and can effectively reduce the threat to personal safety and equipment in the event of a fire; In environments where precision electronic equipment is installed, this feature can further prevent damage to equipment caused by corrosive gases and ensure system stability.

NF C 32-102-9

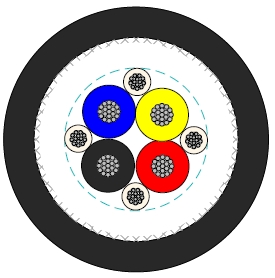

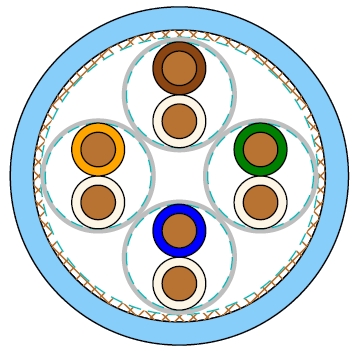

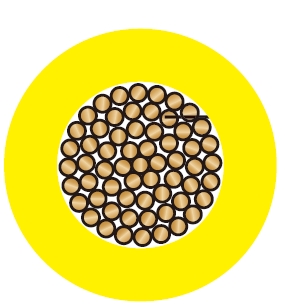

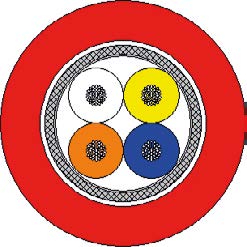

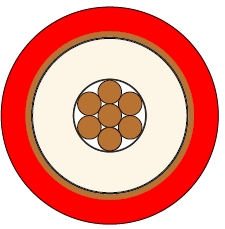

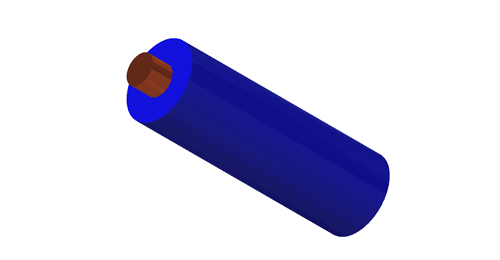

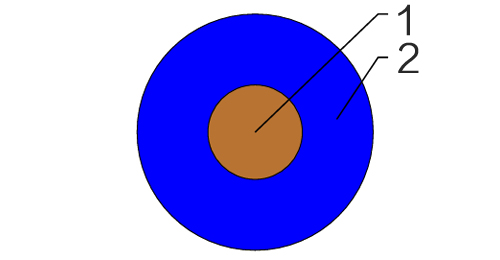

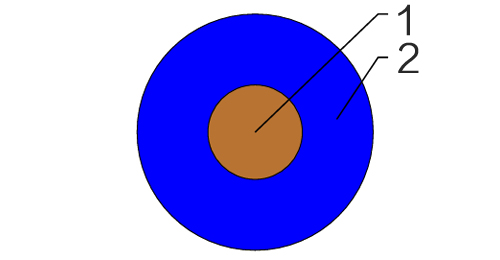

Solid bare copper single wire to IEC 60228 Cl-1(H05Z-U / H07Z-U)

Bare copper strands to IEC 60228 Cl-2 (H07Z-R)

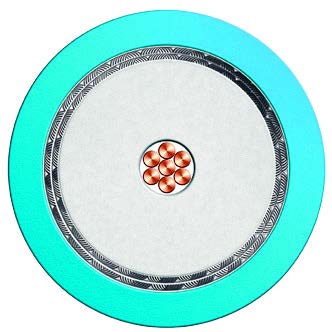

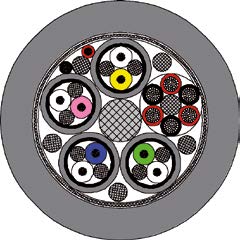

Cross-link polyolefin EI5 core insulation

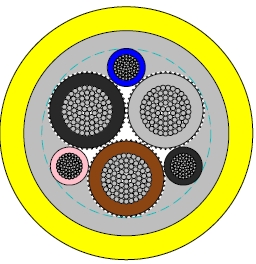

Cores to VDE-0293 colors

LSOH - low smoke, zero halogen

Working voltage : 300/500v (H05Z-U), 450/750v (H07Z-U / H07Z-R)

Test voltage : 2500 volts

Flexing bending radius : 15 x Ø

Static bending radius : 10 x Ø

Flexing temperature : +5ºC to +90ºC

Short circuit temperature : +250ºC

Flame retardant : NF C 32-070

Insulation resistance : 10 MΩ x km

| AWG | No. of Cores × Nominal Cross Sectional Area | Nominal Thickness of Insulation | Nominal Overall Diameter | Nominal Copper Weight | Nominal Weight |

|---|---|---|---|---|---|

| # × mm² | mm | mm | kg/km | kg/km | |

| 05Z-U | |||||

| 20 | 1 x 0.5 | 0.6 | 2.0 | 4.8 | 8 |

| 18 | 1 x 0.75 | 0.6 | 2.2 | 7.2 | 12 |

| 17 | 1 x 1 | 0.6 | 2.3 | 9.6 | 14 |

| H07Z-U | |||||

| 16 | 1 x 1.5 | 0,7 | 2.8 | 14.4 | 20 |

| 14 | 1 x 2.5 | 0,8 | 3.3 | 24 | 30 |

| 12 | 1 x 4 | 0,8 | 3.8 | 38 | 45 |

| 10 | 1 x 6 | 0,8 | 4.3 | 58 | 65 |

| 8 | 1 x 10 | 1,0 | 5.5 | 96 | 105 |

| H07Z-R | |||||

| 16(7/24) | 1 x 1.5 | 0.7 | 3.0 | 14.4 | 21 |

| 14(7/22) | 1 x 2.5 | 0.8 | 3.6 | 24 | 33 |

| 12(7/20) | 1 x 4 | 0.8 | 4.1 | 39 | 49 |

| 10(7/18) | 1 x 6 | 0.8 | 4.7 | 58 | 71 |

| 8(7/16) | 1 x 10 | 1 | 6.0 | 96 | 114 |

| 6(7/14) | 1 x 16 | 1 | 6.8 | 154 | 172 |

| 4(7/12) | 1 x 25 | 1.2 | 8.4 | 240 | 265 |

| 2(7/10) | 1 x 35 | 1.2 | 9.3 | 336 | 360 |

| 1(19/13) | 1 x 50 | 1.4 | 10.9 | 480 | 487 |

| 2/0(19/11) | 1 x 70 | 1,4 | 12.6 | 672 | 683 |

| 3/0(19/10) | 1 x 95 | 1,6 | 14.7 | 912 | 946 |

| 4/0(37/12) | 1 x 120 | 1,6 | 16.0 | 1152 | 1174 |

| 300MCM(37/11) | 1 x 150 | 1,8 | 17.9 | 1440 | 1448 |

| 350MCM(37/10) | 1 x 185 | 2,0 | 20.0 | 1776 | 1820 |

| 500MCM(61/11) | 1 x 240 | 2,2 | 22.7 | 2304 | 2371 |